Collaboration on the digital twin: DACHSER and Allgäuer Werkstätten

By Melanie Guggenberger I 5 minute read

11/09/2025

For the European rollout of the digital twin @ILO, DACHSER is working closely with the Allgäuer Werkstätten in Kempten (Allgäu). With great precision, employees of the non-profit institution that provides work opportunities for people with disabilities assemble the individual parts of a specially developed mount for scanning units. The optical sensors play a key role in the application of the winning @ILO technology for automated identification of packages in the transshipment warehouse.

Quick Read

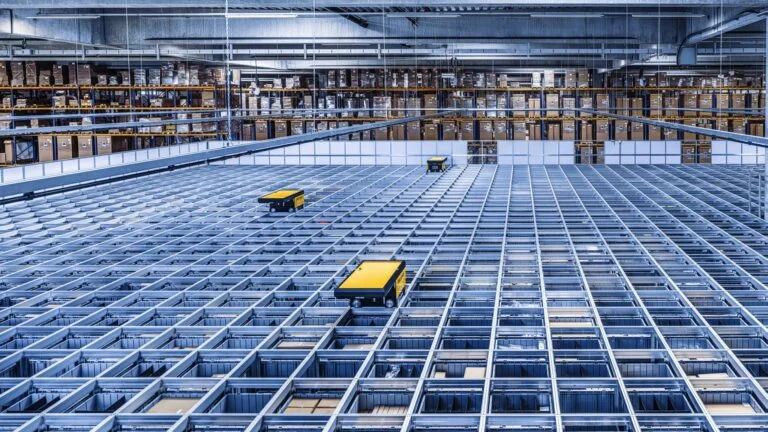

The digital twin @ILO (Advanced Indoor Localization and Operations) creates an up-to-date, digital image of all packages, assets and processes in the transshipment warehouse fully automatically. What began as a research project in the DACHSER Enterprise Lab has developed into a innovative technology solution , which is now being successively rolled out in DACHSER’s logistics terminals throughout Europe.

Depending on the size of the transshipment warehouse, there are several hundred optical scanning units on the hall ceiling. Prior to installation, the mounting components, including the optical scanning units, must be pre-assembled. This task is taken over by the employees of the Allgäuer Werkstätten. “While our general contractors are installing the optical sensors on the hall ceiling, the optical sensors including the brackets have to be pre-installed,” says Daniel Wolf, Senior Expert Corporate Real Estate Development at DACHSER.

“In our search for a suitable partner to assemble the individual components for us, we found what we were looking for in the immediate vicinity. We made a conscious decision to cooperate with the Allgäuer Werkstätten,” adds Patrick Merk, Senior Expert Transit Terminal Processes at DACHSER. “We have also received a lot of encouragement internally for this and would like to use this project to motivate other branches to consider cooperating with a non-profit institution.”

We have deliberately decided to cooperate with the Allgäuer Werkstätten. We have also received a lot of encouragement internally for this.

From initial order to strategic cooperation

After an initial meeting between DACHSER and the Allgäuer Werkstätten, as well as a feasibility study, preparation of an offer, and some coordination, a first order for the @ILO terminal in Dortmund started in November 2024. After a short training phase and minor adjustments in the production process, the 900 brackets were delivered within just two weeks.

“The nice thing about the collaboration is that we at DACHSER are met with open ears,” says Stefan Leibner, who accompanied the order as production manager at the Allgäuer Werkstätten. “During the implementation of the order, for example, we realized that we had to change a screw length. DACHSER supported us in the implementation as a matter of course.” For the transport of the finished brackets, an individual, reusable transport solution was developed together with the carpentry workshop of the Allgäuer Werkstätten.

For many years, the Allgäuer Werkstätten in Kempten and Sonthofen have stood for the promotion and integration of people with disabilities into working life. The aim is to strengthen individual skills and accompany people on their way to a self-determined life.

What we value about the collaboration is that we are met with openness.

Successful together through appreciative cooperation

In the meantime, the Allgäuer Werkstätten have received series approval for the assembly of 10,000 pieces of brackets per year. “In addition to the quality and adherence to deadlines, we were convinced by the overarching coordination. The active cooperation of people with and without disabilities as well as mutual partnership also play an important role for us,” says Daniel Wolf. The project team is particularly pleased that the employees of the Allgäuer Werkstätten are carrying out the assembly work for the @ILO terminals with palpable enthusiasm.

This is also confirmed by Illir Speci, head of department and group leader metal at the institution: “Our employees have already asked when the next order will come after the first one has been completed. The recognition and appreciation are good for them.”

The Allgäuer Werkstätten now assemble brackets for DACHSER every year.

The active cooperation of people with and without disabilities as well as mutual partnership also play an important role for us.

A total of about 650 people work at the Allgäuer Werkstätten GmbH at the Kempten and Sonthofen locations. Five to six employees are currently working on the @ILO project in Kempten to carry out the filigree work. One of them is Christina Knoblich, who has been working part-time at the Allgäuer Werkstätten for a year. “I like working for DACHSER because of the variety. In some departments, you only make one identical movement, but here we have some parts to assemble,” she explains. “It’s a nice feeling when you hold the result, i.e. the finished camera mount, in your hands.”

Thomas Wallner, who has been an employee of the Allgäuer Werkstätten for ten years, also likes the job: “Each department has its own task. That’s the great thing here. For example, I’m interested in technical things, such as what we do for DACHSER. I recently took a closer look at the functionality in a video.”